KJN ENTERPRISES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KJN ENTERPRISES

Static Eliminator Bars

PRODUCT OVERVIEW

HAUG RN Static Bar

The HAUG RN ionizing bars is a powerful and rugged piece of equipment. Its construction satisfies all technical requirements and it has proven its value repeatedly in the removal of electrostatic charges during roll, sheet and web (continuous product) processing. Production interfering surface charges can be removed reliably and effectively, even at high operating speeds.

The coaxial high-voltage plug-and-socket connection of the HAUG system X-2000 offers a unique advantage in that the gastight high-voltage plug can be connected to the HAUG power pack easily and without tools. The flexible, coaxially shielded cable connects the ionizing unit with the voltage supply.

The round construction of the RN ionizing bars permits the exact axial adjustment in the direction of travel of the material. The ionizing bars is safe to touch. Special wear-resistant electrodes guarantee long service life.

HAUG VS Static Bar

The HAUG VS ionizing bar reliably removes electrostatic charges and its performance, when compared to the standard version, is three times the power. This tremendously improves the static removal and designed to address extremely high charges, faster speeds and greater distances.

The VS ionizing bar has all of the typical features that characterize HAUG ionizing bars: the reliable and removable plug-and-socket connection System X-2000, the shielded high-voltage cable, the special stainless-steel electrodes and the convenience of being safe to touch.

The electrical capacity of the VS ionizing bar is three times as great as the standard version, and therefore, it is necessary to base any power pack load calculations on a bar length three times as long.

Example:

VS static bar - 50 cm with 200 cm cable

Power pack load: 3 x 50 cm + 200 cm = 350 cm

Explosion Proof Static Bars

Units for areas with potentially explosive atmospheres (ex zone)

For many years, HAUG has been a competent manufacturer of ionizing units approved for equipment in areas with potentially explosive atmospheres. These are intended to eliminate unwanted electrostatic charges in areas where hazardous gases may form, such as paint plants or printing machines.

Industries

Graphical industry: Screen, tampon and offset printing machines etc.

Paint shops: automotive paint applications, painting of plastic parts, etc.

Ionizing bars EI Ex T

The design of the ionizing bars EI Ex T complies with the International ATEX directivities. In combination with the power pack EN 92 Ex or Multistat Ex, it is suitable for use in manufacturing locations with potentially explosive atmospheres resulting from gases of explosion group IIA, temperature classes T4 to T6.

Further bars variations are available

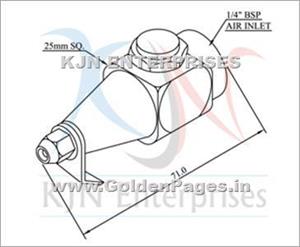

These static bars can also be provided with high-voltage connection at the end of the bars for series connection of ionizing units (daisy-chain units end to end) or without HV-cable, suitable for connection of a flexible, separate high-voltage cable with elbows or tees – a variety of systems to "minimize" the need for excessive cable and extra power supplies, a significant advantage over competitive systems such as in "halo" blow-offs for paint lines where several static bars with air blades can be connected end to end.

Recommendation

HAUG ionizing bars are used with machines in the packaging, film, printing and textile industries, as well as many other industrial applications. It is recommended that two ionizing bars be installed above and below the material web.

The RN ionizing bars is suitable for feed speeds = 100 m/min.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.